UMC4000

Our UMC4000 blade control system is used on construction and land-leveling machinery or machinery attachments to automatically control the blade in earthmoving and grading applications. It could also be used on drainage, trenching or milling machinery. By the use of machine laser receivers, ultrasonic transducers or slope sensors a reference elevation will automatically be transferred to the cutting edge of the blade. The system is ready for integration of GNSS or TPS system using a digital terrain model as reference.

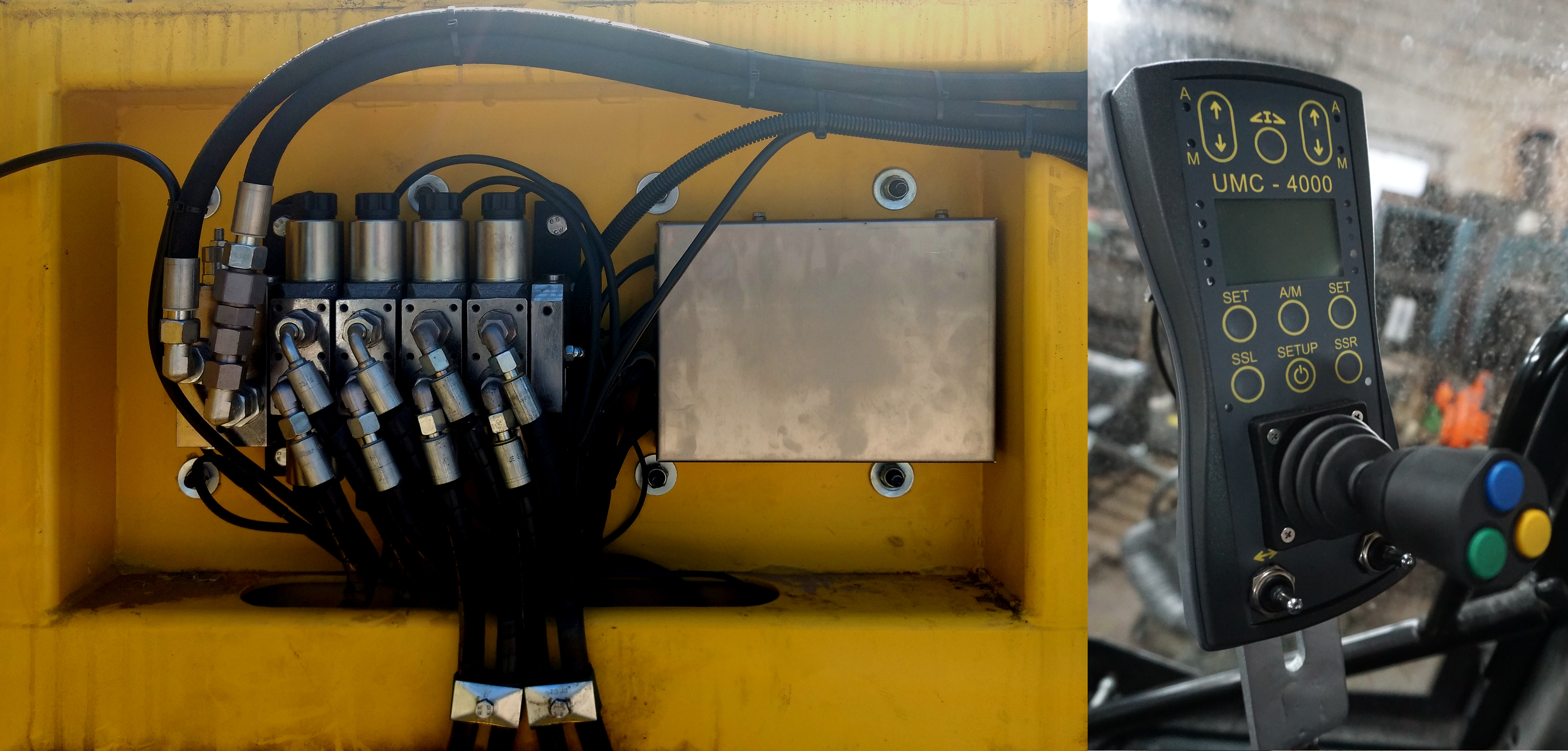

UMC4000 consists of a control unit and a man-machine-interface with joystick and programmable functionality. The system controls up to 8 different hydraulic functions, no matter if tied to ON/OFF solenoid or proportional valves (PC or PV). Thus, UMC4000 features blade elevation control of up to three cylinders (main, if there is, plus right and left) and automatic adjustment of both hydraulic side doors of the blade. In addition, our MMI steers other functionality such as hydraulic masts or folding the blade for road transportation, as an example. The UMC4000 is versatility at its best.

System components:

- Control panel (MMI) with LCD and joystick with three switch-keys

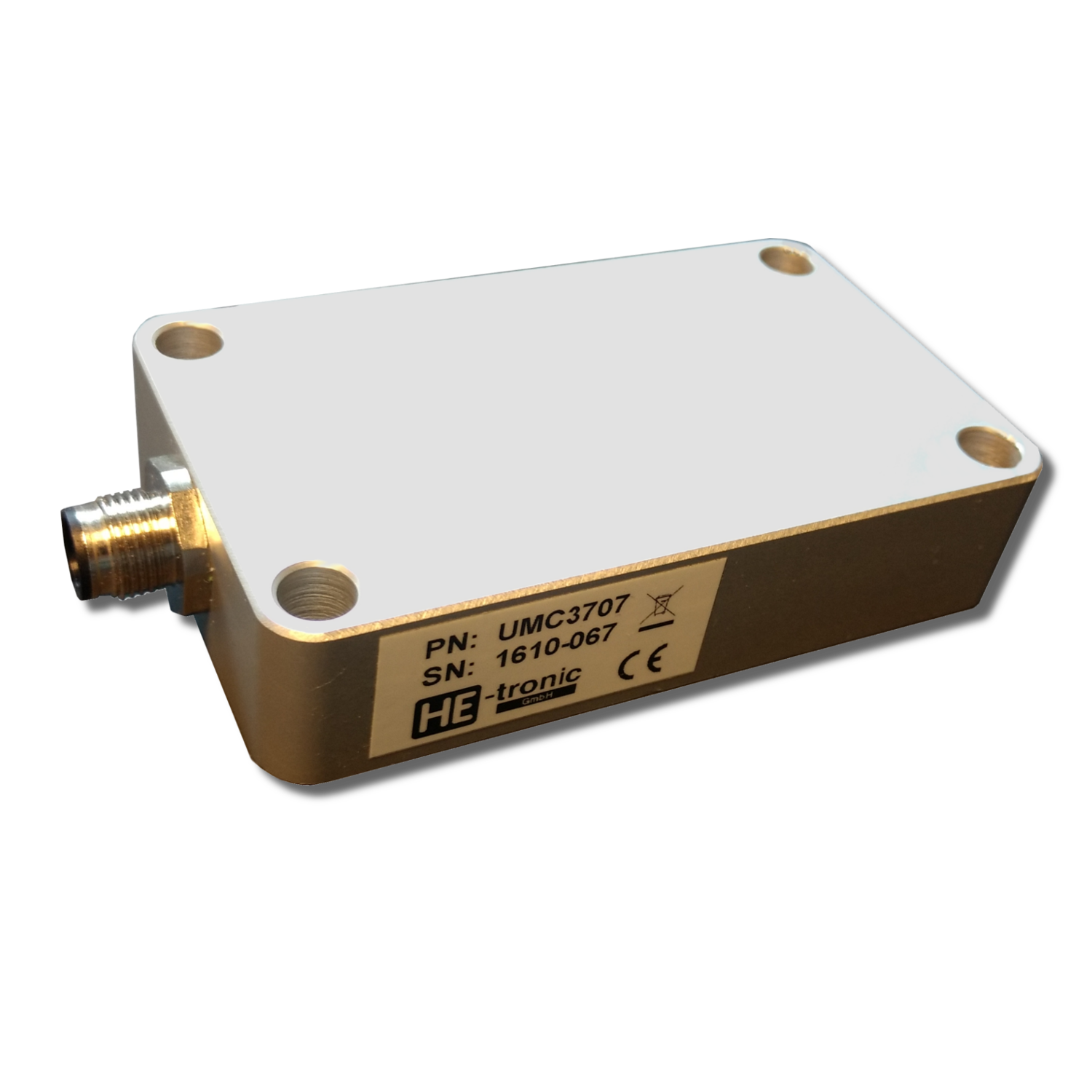

- Control box with built-in three-axis slope sensor

- UMC4001 Single control box, or

- UMC4003 Dual control box, or

- UMC4005 Eightfold control box

- Cable and installation kit

- Valve cables

- Sensor cables

- Cabin Y-cable for MMI and power supply

- Ram-Mount for MMI

- Option: Stainless steel protection housing for control box

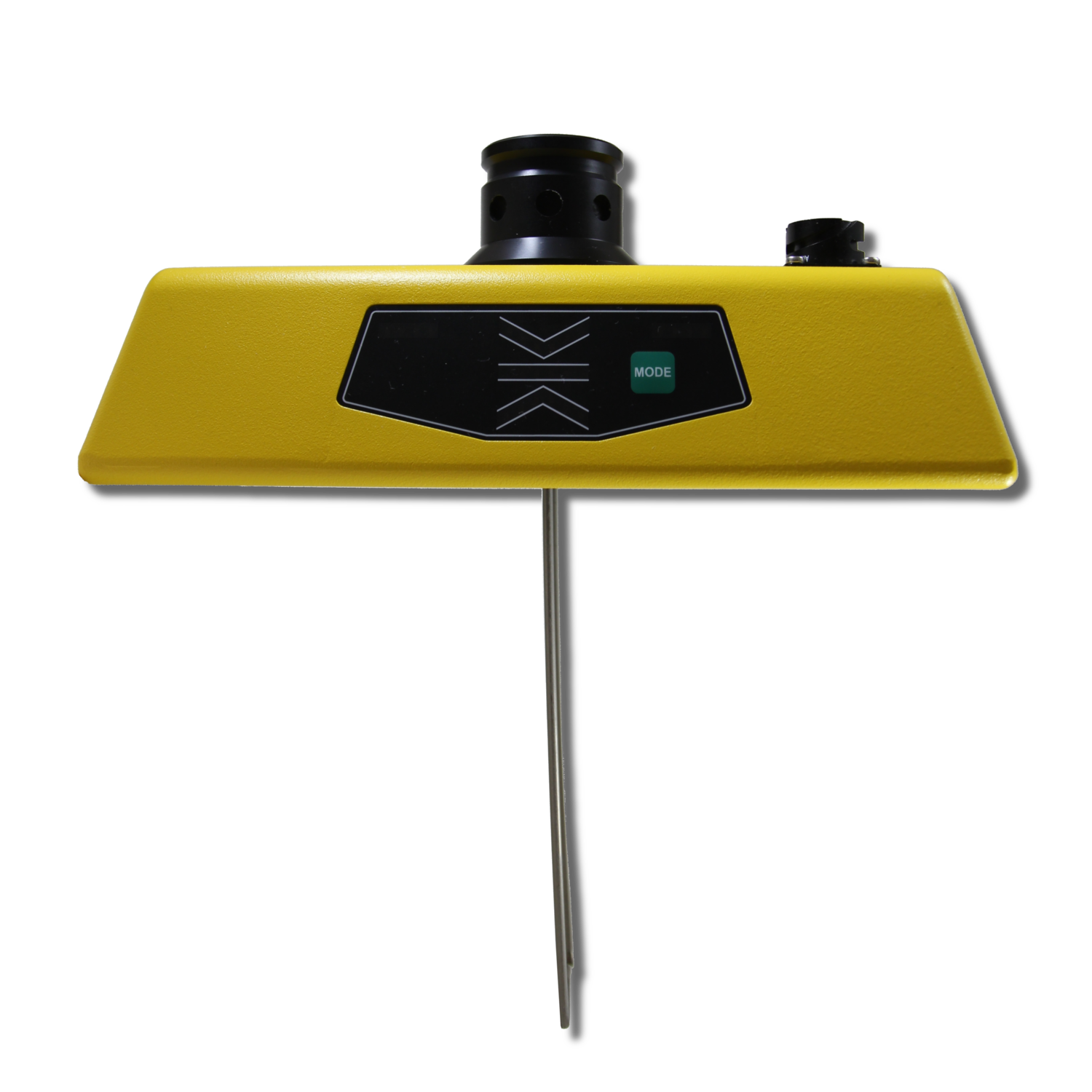

- Option: Mechanical, electric or hydraulic masts for laser receivers, GNSS antennas or tracking prisms

- Option: Other mounting bracket, p. e. for ultra-sonic sensors

- Option: Heavy-duty carrying case

- Acessories: Rotating lasers, receivers, tripods and levelling rods

Levelling information of the connected sensors is processed in the control box and automatically directs the machine's hydraulic to maintain the elevation of the blade. The operator can do settings and takes action through the joystick and other switch-keys on the control panel.

The control box has an integrated slope sensor that can be activated by a software key. That means that there is no need for an external slope sensor whenever the box can be mounted on the blade itself.

We deliver the UMC4000 pre-configured in accordance to your specified demand. More than 40 configurations can be stored. So, a change of blade or machinery or a different job task will not cause a new calibration. Simply select the desired configuration out of the memory of the control box before starting your job at site.

UMC4000

Of course, we offer installation and configuration service, as well as training on the job.

If you like to get a complete kit of grading attachment and control system, please don't hesitate to contacting us. Together we will find out what is the most appropriate blade and sensors for the task that you like to accomplish. We could supply then the completely equipped automatic grading blade. All from one source.